( ESNUG 540 Item 5 ) -------------------------------------------- [05/16/14]

Subject: Isadore's 28 low voltage timing sign-off & characterization tips

> In this ESNUG post I wish to examine how the recent trend of dropping the

> on-chip voltage (VDD) -- to cut power -- ripples throughout every stage

> of chip design. Simply put:

>

> Power == (Voltage^2) / Resistance

>

> That is, as a chip's VDD drops linearly, power use drops geometrically.

>

> What follows are the nuances of how dropping to ultra-low voltages (to

> save on power, and while still maintaining performance over a range of

> temperatures) impacts how our chips are designed.

>

> - Jim Hogan

> Vista Ventures, LLC Los Gatos, CA

From: [ Isadore Katz of CLKDA ]

Hi, John,

Ultra-low voltage design creates a whole new range of problems for timing

sign-off and characterization. Many of the traditional assumptions about

delay, process variance, timing constraints, parasitic/wire load behavior,

and even the delay model itself, break down.

There's a real risk that designs which appear to pass timing sign-off at

low voltage will actually fail when in silicon. And while everyone has

their "tricks" to compensate for slow paths in silicon, almost all of them

involve detecting the violation and then dialing up the voltage and power;

which effectively defeats the whole goal. It is always better to detect

and correct these paths pre-tape out.

Fundamentally, timing for ultra-low voltage digital design looks much more

like an analog problem. Determining the real speed paths and operating

frequency below 0.7 volts requires a new look at timing and delay modeling.

---- ---- ---- ---- ---- ---- ----

4 WAYS ULTRA-LOW VOLTAGE DESIGN CAN KILL YOUR CHIP

There are 4 ways (at least) where you can miss hidden timing violations in

ultra-low voltage designs. It's essentional that you correct your timing

methodology to catch these before you end up with slow, or worse yet, bad

silicon.

1. HAVING 2X BAD DELAY CALCS

Lets start with the basics. Delay can vary by 2X across the voltage ranges

that most chips are designed at. And what's worse, at ultra-low voltage the

gap between "early" and "late" arrival (corrected for process variation) can

be huge. Underestimate that and you miss a violation. Remember, when you

check for timing violations, you are forcing one side of the path to arrive

"early" and one side of the path to arrive "late". When data arrives "late"

relative to a fast or early clock, that is a set-up violation. When data

arrives early relative to a slow/late clock, that is a hold violation.

Set-up violations force you to slow the clock frequency. Hold violations

are fatal.

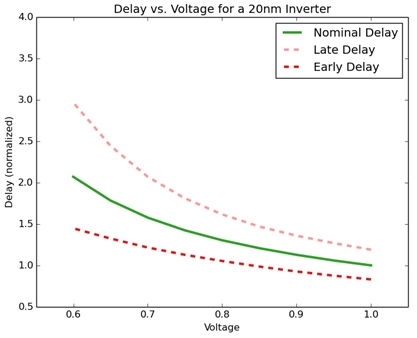

Fig 1. Shmoo plot of Delay vs. Voltage of an inverter

Above is a Shmoo plot of the delay of a basic inverter from 1 volt down to

0.6 volt at 20 nm using a load of 0.007 pF and input slew of 29 psec. It

shows how bad delay can get. (I've "normalized" the values to a delay of

1 at 1 volt to help you see how dramatic the swing can be.)

First, the nominal delay (the green line in the middle) literally doubles

from 1 volt down to 0.6 volts. That is a really big swing to try and meet

timing at different voltages, and will generate a whole range of additional

violations. That is just basics.

Second -- and this is the killer -- the gap between early and late arrival

when you add in process variation is huge. There is literally a gap of 2X

between early and late arrival.

Remedies: There are three things that can be done to fix your delay calc at

ultra-low voltages.

1. Use cells which are less sensitive to variation. There are

cells in a library which are solid at normal operating

ranges, but which simply can no longer be used at ultra-low

voltage operation, and have to be excluded.

2. Characterize everything for all voltages -- don't guess. There

are no short cuts on library characterization.

3. Use clock and data side derates. Whether it is AOCV, POCV,

SOCV or Liberty Variance Format, you need to adjust delay

for process variance at low voltage. It is simply too big

a swing to ignore.

So using real numbers, in a low-voltage design if you think you have a worse

path of 333 psec -- because of that 2X swing -- in real life it's 666 psec.

---- ---- ---- ---- ---- ---- ----

2. NON-GAUSSIAN DISTRIBUTIONS KILL YOUR DELAY CALC

Adjusting your delay calcs for process variance at ultra-low voltage has one

major complication -- the distribution is non-Gaussian. Translation: if you

assume process distribution is a "normal" or Gaussian distribution you will

get it very wrong.

The impact of process sensitivity, which was already quite noticeable once

your're below 28 nm, increases even more at low voltages. As importantly,

process variance becomes highly non-linear -- meaning its distribution is

extremely non-Gaussian -- which dramatically magnifies the impact of process

variation. Some of the allegedly adequate sigma estimation methods that

rely on sensitivities and assume a Gaussian distribution rather than real

analysis -- such as those proposed by Cadence and Synopsys -- are a joke.

Fig 1 above also showes the early and late delays (nominal +/- 3 sigma) and

illustrates the process sensitivity of the same inverter across multiple

voltages.

Fig 1. Shmoo plot of Delay vs. Voltage of an inverter

Above is a Shmoo plot of the delay of a basic inverter from 1 volt down to

0.6 volt at 20 nm using a load of 0.007 pF and input slew of 29 psec. It

shows how bad delay can get. (I've "normalized" the values to a delay of

1 at 1 volt to help you see how dramatic the swing can be.)

First, the nominal delay (the green line in the middle) literally doubles

from 1 volt down to 0.6 volts. That is a really big swing to try and meet

timing at different voltages, and will generate a whole range of additional

violations. That is just basics.

Second -- and this is the killer -- the gap between early and late arrival

when you add in process variation is huge. There is literally a gap of 2X

between early and late arrival.

Remedies: There are three things that can be done to fix your delay calc at

ultra-low voltages.

1. Use cells which are less sensitive to variation. There are

cells in a library which are solid at normal operating

ranges, but which simply can no longer be used at ultra-low

voltage operation, and have to be excluded.

2. Characterize everything for all voltages -- don't guess. There

are no short cuts on library characterization.

3. Use clock and data side derates. Whether it is AOCV, POCV,

SOCV or Liberty Variance Format, you need to adjust delay

for process variance at low voltage. It is simply too big

a swing to ignore.

So using real numbers, in a low-voltage design if you think you have a worse

path of 333 psec -- because of that 2X swing -- in real life it's 666 psec.

---- ---- ---- ---- ---- ---- ----

2. NON-GAUSSIAN DISTRIBUTIONS KILL YOUR DELAY CALC

Adjusting your delay calcs for process variance at ultra-low voltage has one

major complication -- the distribution is non-Gaussian. Translation: if you

assume process distribution is a "normal" or Gaussian distribution you will

get it very wrong.

The impact of process sensitivity, which was already quite noticeable once

your're below 28 nm, increases even more at low voltages. As importantly,

process variance becomes highly non-linear -- meaning its distribution is

extremely non-Gaussian -- which dramatically magnifies the impact of process

variation. Some of the allegedly adequate sigma estimation methods that

rely on sensitivities and assume a Gaussian distribution rather than real

analysis -- such as those proposed by Cadence and Synopsys -- are a joke.

Fig 1 above also showes the early and late delays (nominal +/- 3 sigma) and

illustrates the process sensitivity of the same inverter across multiple

voltages.

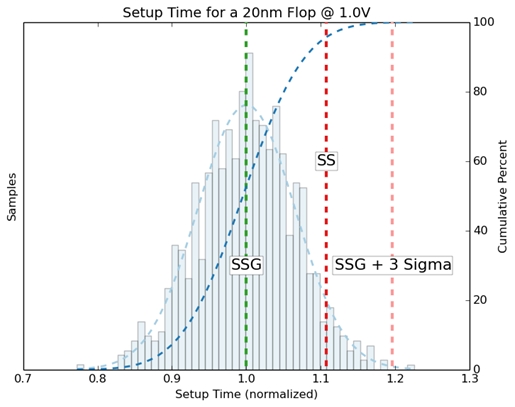

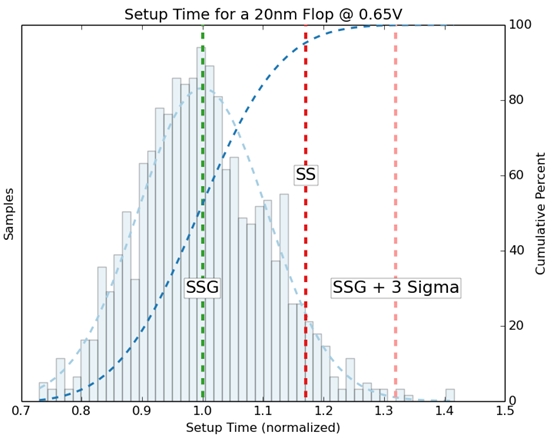

Fig 2: Low voltage process sensitivity -- note the 0.65 V shape

Fig 2 shows how wrong it can be. When a distribution is non-Gaussian, it

is skewed. As in one side looks normal, but the other side has a very long

tail. That means that the "early" delay may be earlier, but the "late"

delay may be a lot later (or visa versa). Which means you are missing

timing violations in your chip!

Fig 2 shows the same inverter we presented in Fig 1. At 1.0 volt the

distribution looks normal. At 0.6 volt the distribution is heavily skewed

and non-Gaussian. Looking back at Fig 1, that is why the "early" delay is

1.5 (compared to a nominal delay of 2), but the late delay is 3!!!

This skew in the distribution translates directly to a skew in the "early"

and "late" timing. Underestimate this, and you miss violations.

Remedies: You have to make sure the derates for variance correct for the

skew. AOCV, POCV, SOCV and Liberty Variance Format all have the notion of

early and late derates or sigmas -- which is a natural way to correct for

non-Gaussian distribution.

Caveat: While some tools, like Variance FX, will correct for non-Gaussian

distributions, Monte Carlo SPICE systems need to be adjusted in two ways.

First, you will need to take a much larger number of samples, potentially

10,000 (and no, this is a three-sigma problem, not a six-sigma problem

which you can address with tools like Solido).

Second, you need to correctly mine the results to get early and late sigma

by actually evaluating the cumulative distribution (CDF) of the samples.

Most built-in MC SPICE reports assume a normal distribution and only report

one number.

---- ---- ---- ---- ---- ---- ----

3. BAD SLACK DUE TO BAD SET-UP/HOLD CONSTRAINTS

Equally important is the sensitivity of timing constraints when you drop to

low voltages.

Ultra-low voltage has the same impact on set-up and hold constraints as it

does on delay. They shift dramatically because of the low voltage operation

and process sensitivity. If you do not correct the constraints, you will

miscalculate slack and miss violations.

Set-up and hold constraints are the metric for slack on a path -- "positive"

slack means that a path meets timing, "negative" slack that it fails timing.

Constraints are normally associated with registers such as flip-flops or

latches, though there are also constraints for specific elements such as

clock gaters. A timing constraint determines the window when the data

and clock have to arrive for a signal value to be captured.

Again, if data arrives too late, it is a set-up violation. If it arrives

too early it is a hold violation.

Timing slack is the margin, positive or negative for the total path relative

to that window. Traditionally, constraints are characterized at the process

corners SS and FF. SS or slow nFET/slow pFET and FF or fast nFET/fast pFET,

refer to the sign-off corners that are set by a foundry, like TSMC, Samsung,

Global or UMC. If you pass timing at these corners, as measured by static

timing analysis, then the chip should function.

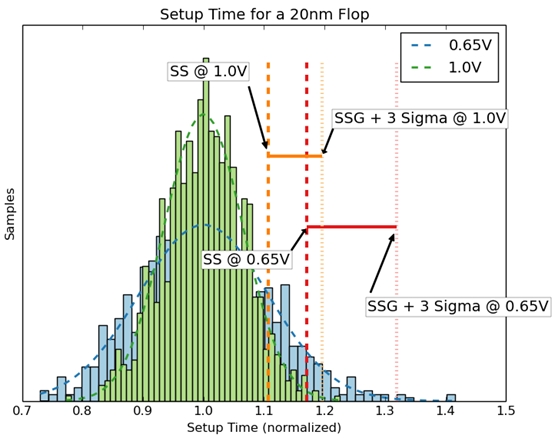

Fig 3 and fig 4 below capture process sensitivity for the basic set-up

constraint of a 20 nm flip-flop at 1 volt and 0.6 volts. Again these are

normalized constraint values. The average constraint is a value of 1.

Fig 2: Low voltage process sensitivity -- note the 0.65 V shape

Fig 2 shows how wrong it can be. When a distribution is non-Gaussian, it

is skewed. As in one side looks normal, but the other side has a very long

tail. That means that the "early" delay may be earlier, but the "late"

delay may be a lot later (or visa versa). Which means you are missing

timing violations in your chip!

Fig 2 shows the same inverter we presented in Fig 1. At 1.0 volt the

distribution looks normal. At 0.6 volt the distribution is heavily skewed

and non-Gaussian. Looking back at Fig 1, that is why the "early" delay is

1.5 (compared to a nominal delay of 2), but the late delay is 3!!!

This skew in the distribution translates directly to a skew in the "early"

and "late" timing. Underestimate this, and you miss violations.

Remedies: You have to make sure the derates for variance correct for the

skew. AOCV, POCV, SOCV and Liberty Variance Format all have the notion of

early and late derates or sigmas -- which is a natural way to correct for

non-Gaussian distribution.

Caveat: While some tools, like Variance FX, will correct for non-Gaussian

distributions, Monte Carlo SPICE systems need to be adjusted in two ways.

First, you will need to take a much larger number of samples, potentially

10,000 (and no, this is a three-sigma problem, not a six-sigma problem

which you can address with tools like Solido).

Second, you need to correctly mine the results to get early and late sigma

by actually evaluating the cumulative distribution (CDF) of the samples.

Most built-in MC SPICE reports assume a normal distribution and only report

one number.

---- ---- ---- ---- ---- ---- ----

3. BAD SLACK DUE TO BAD SET-UP/HOLD CONSTRAINTS

Equally important is the sensitivity of timing constraints when you drop to

low voltages.

Ultra-low voltage has the same impact on set-up and hold constraints as it

does on delay. They shift dramatically because of the low voltage operation

and process sensitivity. If you do not correct the constraints, you will

miscalculate slack and miss violations.

Set-up and hold constraints are the metric for slack on a path -- "positive"

slack means that a path meets timing, "negative" slack that it fails timing.

Constraints are normally associated with registers such as flip-flops or

latches, though there are also constraints for specific elements such as

clock gaters. A timing constraint determines the window when the data

and clock have to arrive for a signal value to be captured.

Again, if data arrives too late, it is a set-up violation. If it arrives

too early it is a hold violation.

Timing slack is the margin, positive or negative for the total path relative

to that window. Traditionally, constraints are characterized at the process

corners SS and FF. SS or slow nFET/slow pFET and FF or fast nFET/fast pFET,

refer to the sign-off corners that are set by a foundry, like TSMC, Samsung,

Global or UMC. If you pass timing at these corners, as measured by static

timing analysis, then the chip should function.

Fig 3 and fig 4 below capture process sensitivity for the basic set-up

constraint of a 20 nm flip-flop at 1 volt and 0.6 volts. Again these are

normalized constraint values. The average constraint is a value of 1.

Fig 3: Set-up time process sensitivity at 1.0 V

Fig 3: Set-up time process sensitivity at 1.0 V

Fig 4: Set-up time process sensitivity at 0.65 V

Both of these pictures shows the probability distribution of the set-up

constraint. The bell shaped curve (though not Gaussian) is the Probability

Distribution Function (PDF).

The curve that goes up and right is Cumulative Distribution Function (CDF).

So where should the constraint be set? Traditionally, the constraint is set

at the line marked SS for the Slow-Slow corner. BUT, does that really

capture the potential impact of process variation?

Another way to set a constraint is to use a statistical value. To calculate

that, we have to use the statistical corner (called SSG) plus 3 sigma. SSG

is also provided by the foundry. It represents the corner if there is only

die-to-die variation and excludes on die variation. You add on-die or local

variation back in by using sigma.

An important note: The SS corner does NOT equal SSG-plus-3-sigma -- this is

a common myth.

Now lets look at the graphs again. The SS corner gives us a constraint of

1.1 at 1 volt. SSG-plus-3-sigma gives us a constraint of 1.2. This is much

more pessimistic.

At 0.6 volts, it gets much worse. Not only does the SS constraint shift out

to nearly 1.2, but SSG shifts out past 1.3.

Two things are work here. First, the voltage drop alone results in much

more pessimistic constraint. Second, process variance pushes the constraint

out even further.

Why? Because once again the distribution is skewed, non-Gaussian, at low

voltage. Low-voltage plus process-variation means that the safe window for

data to be captured is that much smaller.

Fig 4: Set-up time process sensitivity at 0.65 V

Both of these pictures shows the probability distribution of the set-up

constraint. The bell shaped curve (though not Gaussian) is the Probability

Distribution Function (PDF).

The curve that goes up and right is Cumulative Distribution Function (CDF).

So where should the constraint be set? Traditionally, the constraint is set

at the line marked SS for the Slow-Slow corner. BUT, does that really

capture the potential impact of process variation?

Another way to set a constraint is to use a statistical value. To calculate

that, we have to use the statistical corner (called SSG) plus 3 sigma. SSG

is also provided by the foundry. It represents the corner if there is only

die-to-die variation and excludes on die variation. You add on-die or local

variation back in by using sigma.

An important note: The SS corner does NOT equal SSG-plus-3-sigma -- this is

a common myth.

Now lets look at the graphs again. The SS corner gives us a constraint of

1.1 at 1 volt. SSG-plus-3-sigma gives us a constraint of 1.2. This is much

more pessimistic.

At 0.6 volts, it gets much worse. Not only does the SS constraint shift out

to nearly 1.2, but SSG shifts out past 1.3.

Two things are work here. First, the voltage drop alone results in much

more pessimistic constraint. Second, process variance pushes the constraint

out even further.

Why? Because once again the distribution is skewed, non-Gaussian, at low

voltage. Low-voltage plus process-variation means that the safe window for

data to be captured is that much smaller.

Fig 5: Set up time at 1 V versus 0.6 V

Fig 5 above overlays the distributions and constraints of the flip-flop at

1.0 and 0.6 volts. It clearly shows the disparity between the two voltage

operating points, and the increased sensitivity to process variance at the

lower voltage. And how the constraint shifts out, making it much harder

to meet timing.

This also shows that traditional SS or FF constraints, are optimistic.

Translation: if you do not adjust constraints for process variance, you

will overstate the slack on a timing path. This means missing a violation,

or ironically enough, creating one during optimization. Keep in mind that

optimization tools look for paths that have slack, and use that slack to

reduce power or fix other timing violations. But if the slack they used

is not really there, your optimizer may turn a functioning path into a

hidden timing violation.

Remedies: The traditional way to deal with optimistic set-up and hold

constraints is to add guardbands onto all of the clocks and arrival times

by using clock uncertainty and or additional delays onto clock or data.

This effectively penalizes all of the delays to reduce slack. This is a

brute force approach that impacts all paths regardless of their actual

behavior -- and for most of the designs at ultra-low voltage prevents

everything from meeting timing -- which is a bad outcome.

A new approach is to "add in" constraint uncertainty. This effectively

adjusts the constraints themselves for process variation, and removes the

risk on a situational basis. There are methodology questions that must

be addressed (like exactly how much variance to "add in"), but it is a

much more refined method.

---- ---- ---- ---- ---- ---- ----

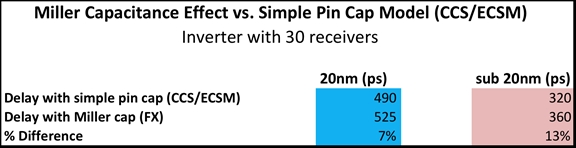

4. BAD DELAYS DUE TO ACTIVE LOADS ON LOW VOLTAGE DESIGNS

None of the existing delay models -- CCS, ECSM -- nor the gate-level static

timing tools, PrimeTime and Tempus, address the impact of active loads

(aka Miller capacitance) posed by ultra-low voltage operation. And many

designers tell me that Miller capacitance is the biggest contributor to

delay loads below 20 nm.

Neither CCS nor ECSM understand an active load. There are workarounds that

attempt to compensate for the Miller capacitance, but their effectiveness

has diminished as the contribution of the Miller capacitance has increased.

Some people compensate by overstating the pin capacitance, but overstating

a value does not always lead to safer timing. You can end up overstating

delay on the wrong contributor -- launch clock, capture clock, data -- and

actually mask a violation.

Fig 5: Set up time at 1 V versus 0.6 V

Fig 5 above overlays the distributions and constraints of the flip-flop at

1.0 and 0.6 volts. It clearly shows the disparity between the two voltage

operating points, and the increased sensitivity to process variance at the

lower voltage. And how the constraint shifts out, making it much harder

to meet timing.

This also shows that traditional SS or FF constraints, are optimistic.

Translation: if you do not adjust constraints for process variance, you

will overstate the slack on a timing path. This means missing a violation,

or ironically enough, creating one during optimization. Keep in mind that

optimization tools look for paths that have slack, and use that slack to

reduce power or fix other timing violations. But if the slack they used

is not really there, your optimizer may turn a functioning path into a

hidden timing violation.

Remedies: The traditional way to deal with optimistic set-up and hold

constraints is to add guardbands onto all of the clocks and arrival times

by using clock uncertainty and or additional delays onto clock or data.

This effectively penalizes all of the delays to reduce slack. This is a

brute force approach that impacts all paths regardless of their actual

behavior -- and for most of the designs at ultra-low voltage prevents

everything from meeting timing -- which is a bad outcome.

A new approach is to "add in" constraint uncertainty. This effectively

adjusts the constraints themselves for process variation, and removes the

risk on a situational basis. There are methodology questions that must

be addressed (like exactly how much variance to "add in"), but it is a

much more refined method.

---- ---- ---- ---- ---- ---- ----

4. BAD DELAYS DUE TO ACTIVE LOADS ON LOW VOLTAGE DESIGNS

None of the existing delay models -- CCS, ECSM -- nor the gate-level static

timing tools, PrimeTime and Tempus, address the impact of active loads

(aka Miller capacitance) posed by ultra-low voltage operation. And many

designers tell me that Miller capacitance is the biggest contributor to

delay loads below 20 nm.

Neither CCS nor ECSM understand an active load. There are workarounds that

attempt to compensate for the Miller capacitance, but their effectiveness

has diminished as the contribution of the Miller capacitance has increased.

Some people compensate by overstating the pin capacitance, but overstating

a value does not always lead to safer timing. You can end up overstating

delay on the wrong contributor -- launch clock, capture clock, data -- and

actually mask a violation.

Fig 6: Miller capacitance effect vs. simple pin cap model

Fig 6 contrasts the impact of the Miller capacitance at 20 nm vs. sub-20 nm.

The error created by using a simple pin capacitance, as in CCS or ECSM,

jumps from 6% (which was already bad) to 11%. In the case of a high fanout

net (such as a clock tree), this could be fatal.

Remedies: There is none that involve CCS or ECSM. The only remedy is to

change to a new delay model.

---- ---- ---- ---- ---- ---- ----

HOW TO AVOID TIMING SURPRISES AT ULTRA-LOW VOLTAGES

Except for the "active loads" problem, many of your timing failures can be

fixed with better methodologies for calculating delay and modeling

constraints at ultra-low voltages. All of them require coming to grips

with process variation through the application of new derate standards such

as LVF, and alternative timing models, such as transistor-level timing.

1. Prepare for Liberty Variance Format (LVF). Tweaking delays to compensate

for process variance is an area of both great frustration, and continuous

innovation. The oldest way, OCV, may be unusable at ultra-low voltage.

Some have suggested doubling an already large 1.0 V value which can make

it impossible to close timing, and which again may mask violations.

AOCV is an improvement, but it has known limitations. The newly approved

Liberty Variance Format (LVF) addresses the problems in AOCV by adding

full arc/load/slew sigma data. This should provide the accuracy and

flexibility required to fix low voltage operation.

Unfortunately, neither PrimeTime nor Tempus have released full production

support for LVF -- which is a necessary precursor to foundry evaluation

and support. At DAC last year, Cadence announced they would support a

new "open" format SOCV. To date, this "open" specification has yet to

be published.

Also, generating accurate LVF tables at low voltages is non-trivial

because of the non-Gaussian distributions. As a minimum of 10,000

samples may be required if you're using traditional full Monte Carlo

sampling. Sensitivity approaches, such as those proposed by Cadence and

Synopsys, assume Gaussian behavior and even then have severe accuracy

problems.

However, SNPS and CDNS seems committed to delivering full arc/load/slew

support in their timing tools this year. With that in mind, the best

strategy may be a managed transition.

Well-designed AOCV tables for clock and data can serve as a bridge to

full LVG flows. Developing a methodology that clearly delineates

between process variance, and other margin sources takes time to develop

and implement.

2. Until there is a Liberty Standard for Constraints, there is a workaround.

Adjusting constraints for process variance is still left to the user.

Liberty has yet to propose a standard, and the only viable approach

today is to actually modify the Liberty library itself. This method

works, but it is inflexible. To modify the amount of process variance

applied to the constraint, a new library must be generated. And again,

generating accurate constraint uncertainty adjustments requires 10,000

or more samples using Monte Carlo for a non-Gaussian distribution.

---- ---- ---- ---- ---- ---- ----

THE TRANSISTOR-LEVEL TIMING REVIVAL FOR ULTRA-LOW VOLTAGES

The distinctly analog characteristics of ultra-low voltage timing is leading

to a revival of transistor level timing with tools such as Synopsys NanoTime

and CLKDA Path FX.

Transistor-level timing is no longer just the realm of the custom designer;

it addresses all of the delay and parasitic modeling concerns we have raised

in the digital world also.

- The underlying circuit simulator naturally resolves all load/slew

conditions, and can incorporate an active load by properly

connecting a receiver to the driving circuit.

- The performance issues that used to limit the application of

transistor-level timing, are largely being addressed through

improved circuit simulators, and distributed analysis.

Transistor-level timing is path-based, as opposed to PrimeTime or Tempus,

which are graph-based (though both have "path options").

Graph-based timing (GBA) evaluates all paths at once, and is faster, but

it's pessimistic and with lower accuracy.

Path-based timing only considers selected paths, and is slower, but it

eliminates pessimism -- and with transistor-level models, it can be almost

as accurate as SPICE. Most leading design teams have already shifted to

path-based sign-off precisely because of pessimism/accuracy problems with

GBA; so this issue is effectively resolved. (Process variance can be added

back in through multiple mechanisms:

- The LVF sigmas can be used so long as cells can be identified,

- Monte Carlo can be used with NanoTime, and

- Path FX has a novel analytic approach which solves for variance

with MC SPICE accuracy.

The ultimate benefit of transistor-level analysis for ultra-low voltage

timing is that it addresses all four concerns in section one with minimal

overhead. Additionally:

- It inherently addresses the accuracy issues.

- It eliminates the need to add more margin to compensate for the

limitations of delay models.

- There is little or no characterization required because transistor

approaches operate directly from the SPICE model. (Given Murphy's

Law, the probability that a foundry will change its SPICE models

just before a tape-out is painfully high.) Where CCS/ECSM models

will require weeks of characterization to determine the impact of

model change, transistor-timing can be updated literally the same

day the SPICE model arrives.

- There are multiple approaches to bringing process variance into

the transistor flow.

The traditional objection to transistor-timing, i.e. it's slow performance,

has largely been addressed relative to the potential gains in accuracy.

First, the circuit simulators used for delay calculation, such as CLKDA FX,

are all dramatically faster. Second, the use of distributed computing for

path analysis (Path FX, Tempus) keeps wall time in check (nearly linearly

in the case of Path FX).

So while it may not be a complete replacement for traditional graph-based

timing, transistor-level timing is an excellent approach to selectively

verifying critical (and potentially critical) paths, clock nets and other

mission critical parts of your design.

- Isadore Katz

CLK Design Automation Littleton, MA

---- ---- ---- ---- ---- ---- ----

Related Articles

Jim Hogan on how low energy designs will shape everyone's future

Hogan on how ultra low voltage design changes energy and power

Bernard Murphy's 47 quick low voltage RTL design tips (Part I)

Bernard Murphy's 47 quick low voltage RTL design tips (Part II)

Isadore's 28 low voltage timing sign-off & characterization tips

Trent's 12 tips on transistor and full custom low voltage design

Hogan on SNPS, CDNS, Atrenta, CLKDA, Solido as low voltage tools

Fig 6: Miller capacitance effect vs. simple pin cap model

Fig 6 contrasts the impact of the Miller capacitance at 20 nm vs. sub-20 nm.

The error created by using a simple pin capacitance, as in CCS or ECSM,

jumps from 6% (which was already bad) to 11%. In the case of a high fanout

net (such as a clock tree), this could be fatal.

Remedies: There is none that involve CCS or ECSM. The only remedy is to

change to a new delay model.

---- ---- ---- ---- ---- ---- ----

HOW TO AVOID TIMING SURPRISES AT ULTRA-LOW VOLTAGES

Except for the "active loads" problem, many of your timing failures can be

fixed with better methodologies for calculating delay and modeling

constraints at ultra-low voltages. All of them require coming to grips

with process variation through the application of new derate standards such

as LVF, and alternative timing models, such as transistor-level timing.

1. Prepare for Liberty Variance Format (LVF). Tweaking delays to compensate

for process variance is an area of both great frustration, and continuous

innovation. The oldest way, OCV, may be unusable at ultra-low voltage.

Some have suggested doubling an already large 1.0 V value which can make

it impossible to close timing, and which again may mask violations.

AOCV is an improvement, but it has known limitations. The newly approved

Liberty Variance Format (LVF) addresses the problems in AOCV by adding

full arc/load/slew sigma data. This should provide the accuracy and

flexibility required to fix low voltage operation.

Unfortunately, neither PrimeTime nor Tempus have released full production

support for LVF -- which is a necessary precursor to foundry evaluation

and support. At DAC last year, Cadence announced they would support a

new "open" format SOCV. To date, this "open" specification has yet to

be published.

Also, generating accurate LVF tables at low voltages is non-trivial

because of the non-Gaussian distributions. As a minimum of 10,000

samples may be required if you're using traditional full Monte Carlo

sampling. Sensitivity approaches, such as those proposed by Cadence and

Synopsys, assume Gaussian behavior and even then have severe accuracy

problems.

However, SNPS and CDNS seems committed to delivering full arc/load/slew

support in their timing tools this year. With that in mind, the best

strategy may be a managed transition.

Well-designed AOCV tables for clock and data can serve as a bridge to

full LVG flows. Developing a methodology that clearly delineates

between process variance, and other margin sources takes time to develop

and implement.

2. Until there is a Liberty Standard for Constraints, there is a workaround.

Adjusting constraints for process variance is still left to the user.

Liberty has yet to propose a standard, and the only viable approach

today is to actually modify the Liberty library itself. This method

works, but it is inflexible. To modify the amount of process variance

applied to the constraint, a new library must be generated. And again,

generating accurate constraint uncertainty adjustments requires 10,000

or more samples using Monte Carlo for a non-Gaussian distribution.

---- ---- ---- ---- ---- ---- ----

THE TRANSISTOR-LEVEL TIMING REVIVAL FOR ULTRA-LOW VOLTAGES

The distinctly analog characteristics of ultra-low voltage timing is leading

to a revival of transistor level timing with tools such as Synopsys NanoTime

and CLKDA Path FX.

Transistor-level timing is no longer just the realm of the custom designer;

it addresses all of the delay and parasitic modeling concerns we have raised

in the digital world also.

- The underlying circuit simulator naturally resolves all load/slew

conditions, and can incorporate an active load by properly

connecting a receiver to the driving circuit.

- The performance issues that used to limit the application of

transistor-level timing, are largely being addressed through

improved circuit simulators, and distributed analysis.

Transistor-level timing is path-based, as opposed to PrimeTime or Tempus,

which are graph-based (though both have "path options").

Graph-based timing (GBA) evaluates all paths at once, and is faster, but

it's pessimistic and with lower accuracy.

Path-based timing only considers selected paths, and is slower, but it

eliminates pessimism -- and with transistor-level models, it can be almost

as accurate as SPICE. Most leading design teams have already shifted to

path-based sign-off precisely because of pessimism/accuracy problems with

GBA; so this issue is effectively resolved. (Process variance can be added

back in through multiple mechanisms:

- The LVF sigmas can be used so long as cells can be identified,

- Monte Carlo can be used with NanoTime, and

- Path FX has a novel analytic approach which solves for variance

with MC SPICE accuracy.

The ultimate benefit of transistor-level analysis for ultra-low voltage

timing is that it addresses all four concerns in section one with minimal

overhead. Additionally:

- It inherently addresses the accuracy issues.

- It eliminates the need to add more margin to compensate for the

limitations of delay models.

- There is little or no characterization required because transistor

approaches operate directly from the SPICE model. (Given Murphy's

Law, the probability that a foundry will change its SPICE models

just before a tape-out is painfully high.) Where CCS/ECSM models

will require weeks of characterization to determine the impact of

model change, transistor-timing can be updated literally the same

day the SPICE model arrives.

- There are multiple approaches to bringing process variance into

the transistor flow.

The traditional objection to transistor-timing, i.e. it's slow performance,

has largely been addressed relative to the potential gains in accuracy.

First, the circuit simulators used for delay calculation, such as CLKDA FX,

are all dramatically faster. Second, the use of distributed computing for

path analysis (Path FX, Tempus) keeps wall time in check (nearly linearly

in the case of Path FX).

So while it may not be a complete replacement for traditional graph-based

timing, transistor-level timing is an excellent approach to selectively

verifying critical (and potentially critical) paths, clock nets and other

mission critical parts of your design.

- Isadore Katz

CLK Design Automation Littleton, MA

---- ---- ---- ---- ---- ---- ----

Related Articles

Jim Hogan on how low energy designs will shape everyone's future

Hogan on how ultra low voltage design changes energy and power

Bernard Murphy's 47 quick low voltage RTL design tips (Part I)

Bernard Murphy's 47 quick low voltage RTL design tips (Part II)

Isadore's 28 low voltage timing sign-off & characterization tips

Trent's 12 tips on transistor and full custom low voltage design

Hogan on SNPS, CDNS, Atrenta, CLKDA, Solido as low voltage tools

Join

Index

Next->Item

|

|